The emphasis on safe, efficient, and advanced production does not only increase our productivity but also maximizes your profitability. Through our modern production equipment, we can deliver a short lead time for you while fully addressing the needs in your target market with our production advantages.

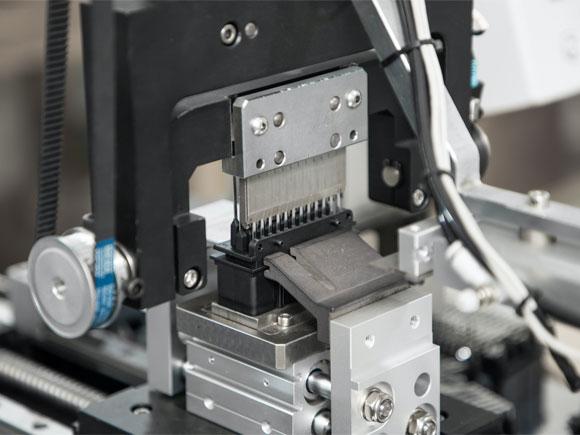

We nurture a high level of sophistication and intelligence of our fully automated manufacturing process to maintain the quality of our connectors.

We make sure to keep the machines in optimal condition so that we can produce satisfactory wire harnesses.

KINKONG not only concentrates on efficient production but also strives to achieve outstanding craftsmanship. With the goal of producing products that stand out in the market while meeting the needs of the target customers, we pursue industry-leading levels of craftsmanship in all aspects of our designing and manufacturing process.

We support all kinds of product appearance customization. Whether it is color, size, or pattern, our designers and engineers are capable of satisfying your needs.

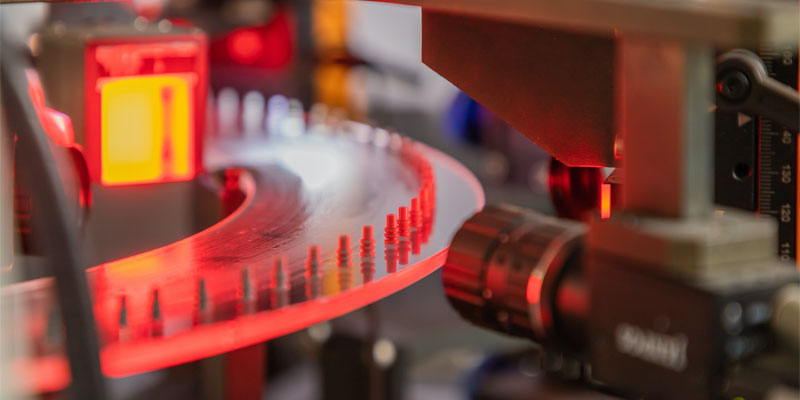

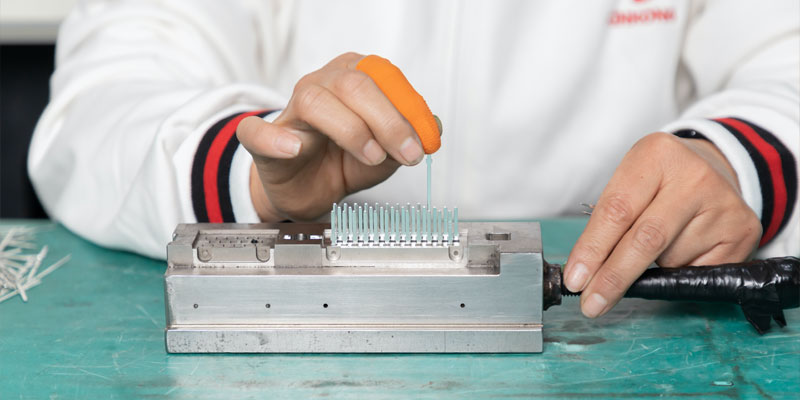

We carry out a series of refinements for the connector pins, as well as automated production with advanced equipment to ensure efficiency. Furthermore, testing of the connection method is conducted to ensure that the connection is precise yet safe and stable.

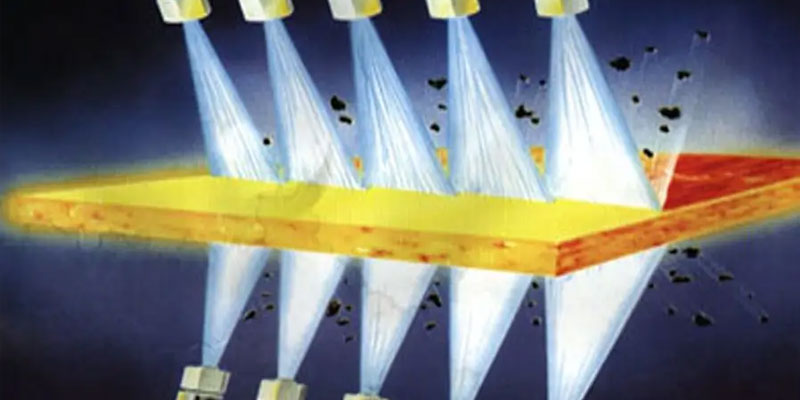

For advanced performance of our products in water and their dust resistance, we have adopted a fully automated injection molding process, which is the basis for quality products and a prerequisite for prompt customer service.

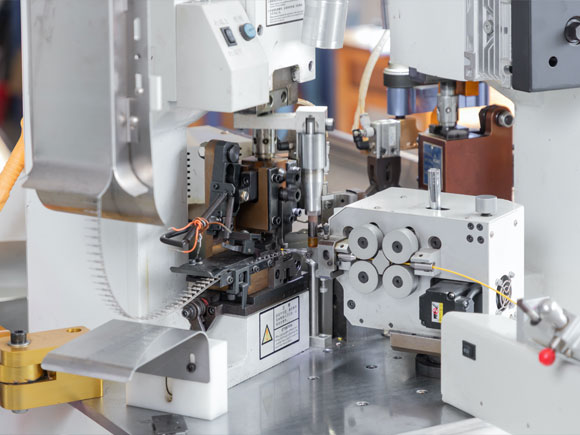

The crimping process defines the quality of our wire harness. KINKONG’s high-level production preserves the strong connection requirements as well as the requirements concerning electrical parameters of the harness.

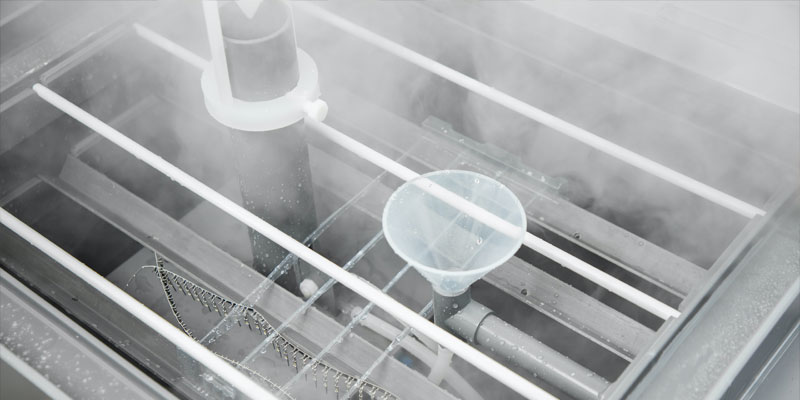

We use a high-pressure water descaling process to ensure the best surface quality for your metal, while reducing energy consumption and costs for you.

In order to control the internal metallographic structure of the metal, we deliberately use an advanced water-cooled section-cooling process to enhance the metallic hardness properties and durability.

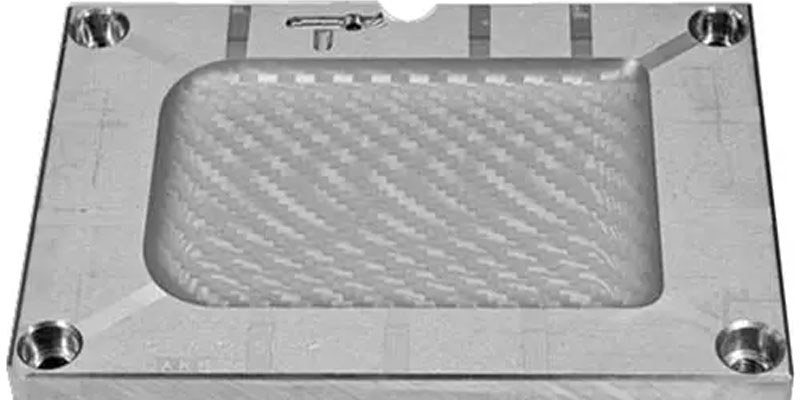

KINKONG specializes in customizing the sunburst of the mold for you, which not only makes the product surface elegant but also improves the hardness of the surface and makes it more durable, bringing you high returns at a low cost.

Bringing high-end customization to you has always been our focus. Our advanced production equipment such as injection molding machines and stamping machines imported from abroad can satisfy a full range of independent designs, from appearance to inner components.

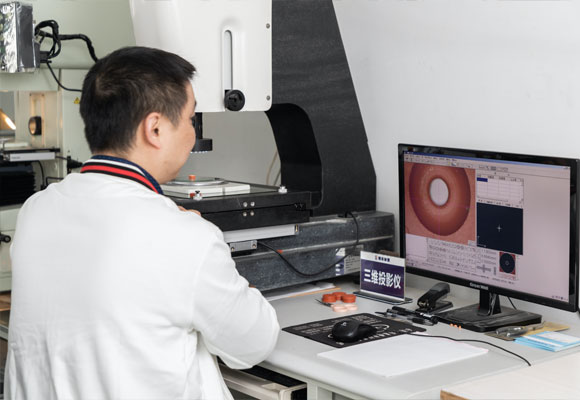

With intelligent and precise instruments, our quality-inspection level exceeds that of our competitors, and we are committed to improving the quality of both raw materials and finished products. A well-organized and well-equipped inspection helps us to get a good reputation and lays the foundation for long-term cooperation in the future.

Copyright © 2021, KINKONG. All rights reserved. Powered by Kinkong