Hello, everyone! I’m here to talk about a topic that’s really important in the world of automotive technology – high – voltage, high – current connectors. These connectors might not be as flashy as the sleek designs of the cars themselves, but they play a crucial role in making EVs work efficiently and safely.

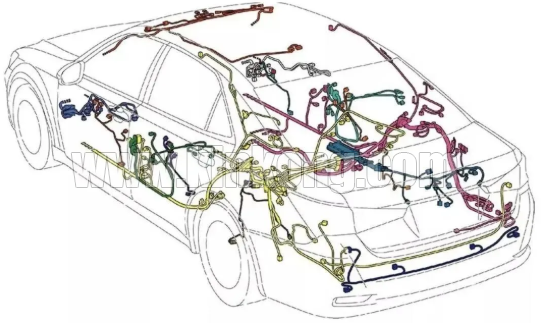

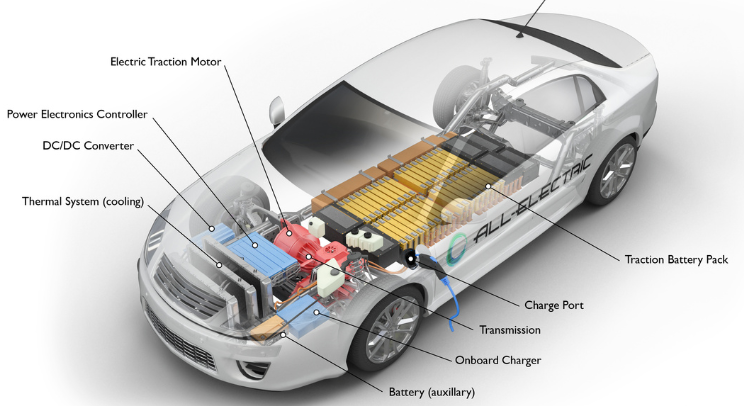

Let me start by telling you about the growing demand for these connectors. The automotive industry is changing fast. Electric vehicles are becoming more and more popular. As this happens, we need more high-voltage, high-current connectors. These connectors help move electricity from the battery to important parts like the motor, inverter, and on-board charger. They make charging faster and help the car use energy better. So, you can see why they’re so important.

Safety is a big deal when it comes to high-voltage connectors. If there’s a problem with the insulation, it could be really dangerous. To avoid this, connectors have to meet strict safety standards. For example, they need to have an IPXXB protection level when they’re disconnected. In wet areas, they need to be waterproof, with a rating of IP67 or higher. They also need features like high-voltage interlock (HVIL) to cut off power safely when the connector is disconnected.

Handling high currents creates heat, and managing this heat is a big challenge. Connectors need to be designed to cool down effectively to prevent overheating. Overheating can lower performance and shorten the connector’s life. This usually means using materials that conduct heat well and designing the connector’s shape to help with cooling.

In the small and electronics-filled environment of an EV, electromagnetic interference can mess up the operation of sensitive electronic parts. High-voltage connectors need to have shielding to reduce electromagnetic interference and ensure the vehicle’s electrical system works reliably.

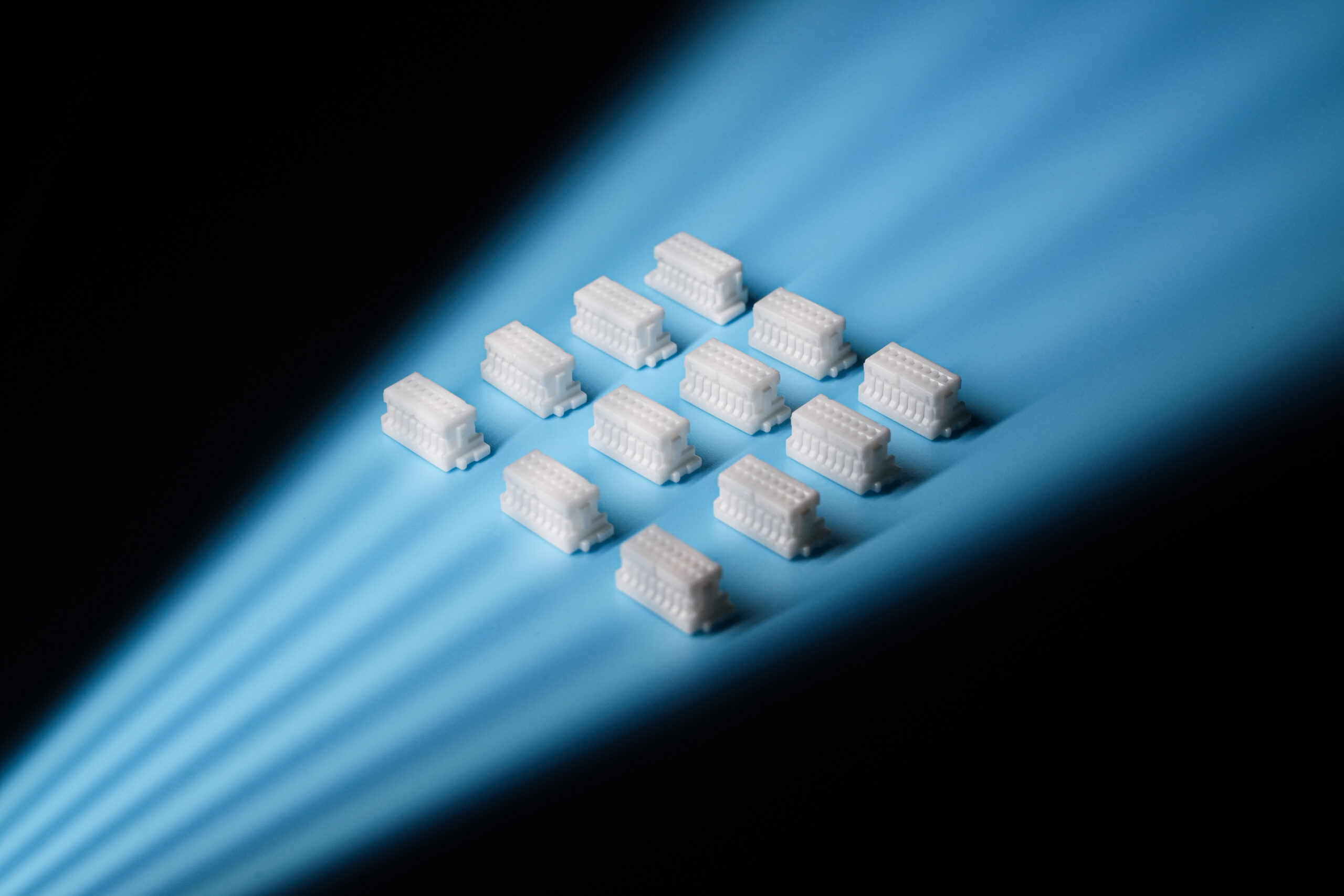

The push for lighter and more efficient vehicles means that connectors also need to be lighter and smaller. Using aluminum instead of copper as the conductor is an innovative way to reduce weight while keeping performance. Also, connector designs are becoming more integrated, which means fewer parts and less complexity in the whole system.

Now, let’s talk about some innovative solutions for high-voltage, high-current connectors. Materials play a big role in making connectors that can handle high voltages and high currents. For example, aluminum-based contact pieces and aluminum rod systems have been developed. These help solve electrochemical corrosion problems and greatly increase the current-carrying ability. These materials not only meet the needs of 800V fast-charging but also make the connector lighter.

To make assembly easier and improve reliability, modular connector systems are getting more attention. These systems allow for easy integration and replacement of parts. This reduces assembly time and cost. For example, Molex offers a modular high-voltage connector system that has better thermal performance and electromagnetic interference shielding. This ensures efficient power transmission and signal integrity.

Safety features like mechanical locking and multiple-stage disconnection actions are becoming standard. These features prevent accidental disconnection and make sure any leftover voltage is safely used up within a few seconds after disconnection. Some connectors also have smart functions that can monitor the connection status and give real-time feedback to the vehicle’s control system.

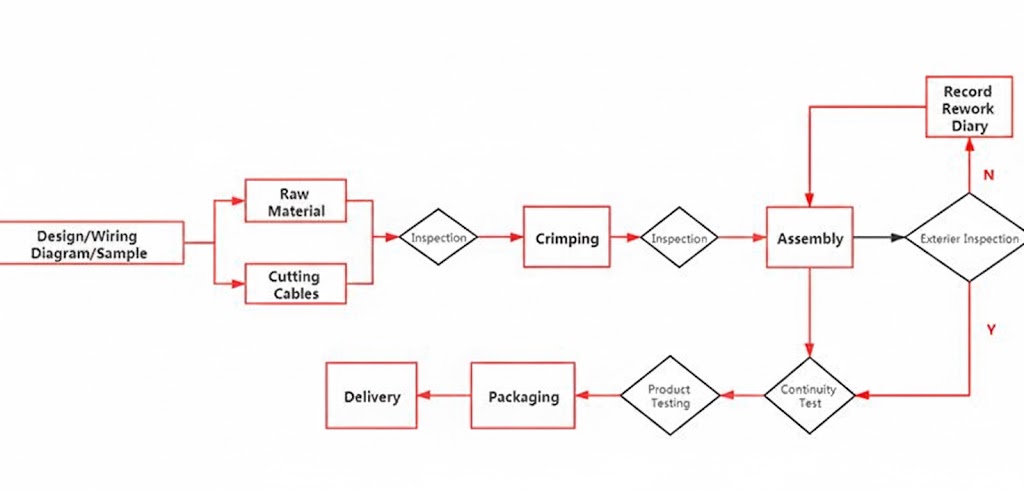

One of the most interesting things I’ve learned is how much testing goes into these connectors. They have to go through rigorous checks to make sure they can handle the demands of an EV. This includes testing for durability, heat resistance, and even how they perform in different weather conditions. It’s a lot of work, but it’s worth it to make sure the connectors can stand up to the test of time.

I’ve also seen how these connectors are designed to be as compact as possible. Space is at a premium in an EV, so every bit of space saved is important. By using lightweight materials and clever design, these connectors can fit into tight spaces without sacrificing performance.

With the progress in battery technology, future vehicles may run on higher-voltage platforms, like 1000V. Connector designs are already being developed to handle these higher voltages. This ensures that the infrastructure is ready for the next generation of electric vehicles.

In conclusion, the shift to automotive electrification brings many challenges. But by focusing on safety, reliability, thermal management, and weight reduction, these connectors are helping to make electric vehicles more widely used. As technology keeps improving, they will play a key role in the future of sustainable transportation.