Automakers are demanding lower prices, but your material costs keep rising. This constant pressure squeezes your margins, making efficiency feel like an impossible target. What if there’s a proven way forward?

The most effective strategy is to source key components directly from China’s mature automotive supply chain. By replacing legacy suppliers for parts like connectors, terminals, and seals with high-quality Chinese alternatives, you can significantly cut costs and boost production efficiency almost immediately.

I speak with supply chain managers like Mike every week. He’s a 30-year veteran from Germany, and he knows the pressure from OEMs is relentless. The old ways of sourcing are becoming too expensive and slow. He, like many others, is looking for a practical solution that doesn’t compromise on quality or reliability. The idea of shifting a large part of the supply chain can feel daunting, but it’s more straightforward than you might think. Let’s explore exactly how this strategy works and why it’s a safe bet in today’s volatile market.

Why Is Sourcing From China a Smart Move Right Now?

You probably have trusted suppliers you’ve worked with for decades. But now, they can’t offer the price flexibility you need, and lead times are getting longer. The old, comfortable way isn’t working anymore.

The time to shift is now because China’s automotive supply chain has reached a unique peak of maturity, quality, and cost-efficiency. It offers a complete ecosystem of reliable, high-performance components that can directly replace expensive legacy parts, providing immediate cost savings and supply stability.

Understanding the Modern Chinese Supply Chain

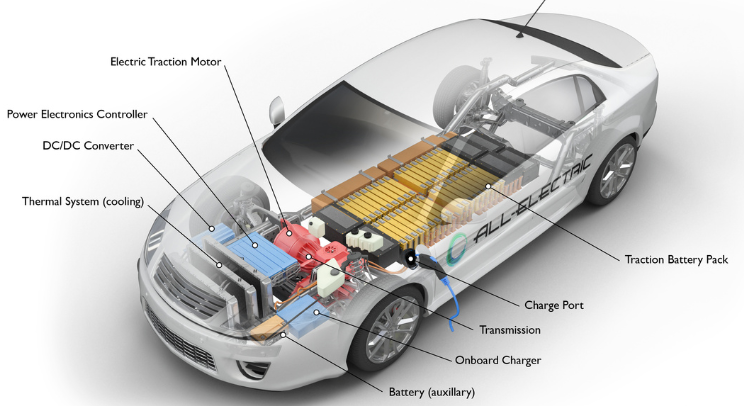

China is no longer just the world’s factory; it’s an innovation hub for the automotive industry. A few years ago, I visited a partner factory in Wenzhou that produces silicone seals. The level of automation and quality control was astounding. It fully matched, and in some cases exceeded, what I had seen in facilities in Europe. This is the new reality. The entire ecosystem, from raw material processing to final assembly, is integrated and highly efficient. You can source everything you need for a wire harness from one region.

Here’s a quick breakdown of what this integrated supply chain offers compared to traditional sourcing models:

| Aspect | Traditional Sourcing Model | Modern Chinese Sourcing Model |

|---|---|---|

| Component Access | Multiple suppliers across different regions | One-stop-shop for connectors, terminals, seals, etc. |

| Cost Structure | High labor and overhead costs | Lower labor costs, high economies of scale |

| Technology | Established but slow to innovate | Rapid adoption of new tech and materials |

| Lead Times | Often long and complex | Shorter due to geographic concentration |

This integration means you aren’t just buying a cheaper part. You are tapping into an efficient system that delivers quality and speed, which directly addresses the core challenges every Tier 1 supplier is facing today.

Can Chinese Components Really Match Global Quality Standards?

I know the biggest hesitation for any supply chain manager is quality. Your reputation is built on reliability. “Made in China” used to carry a certain stigma, and it’s a concern I hear often.

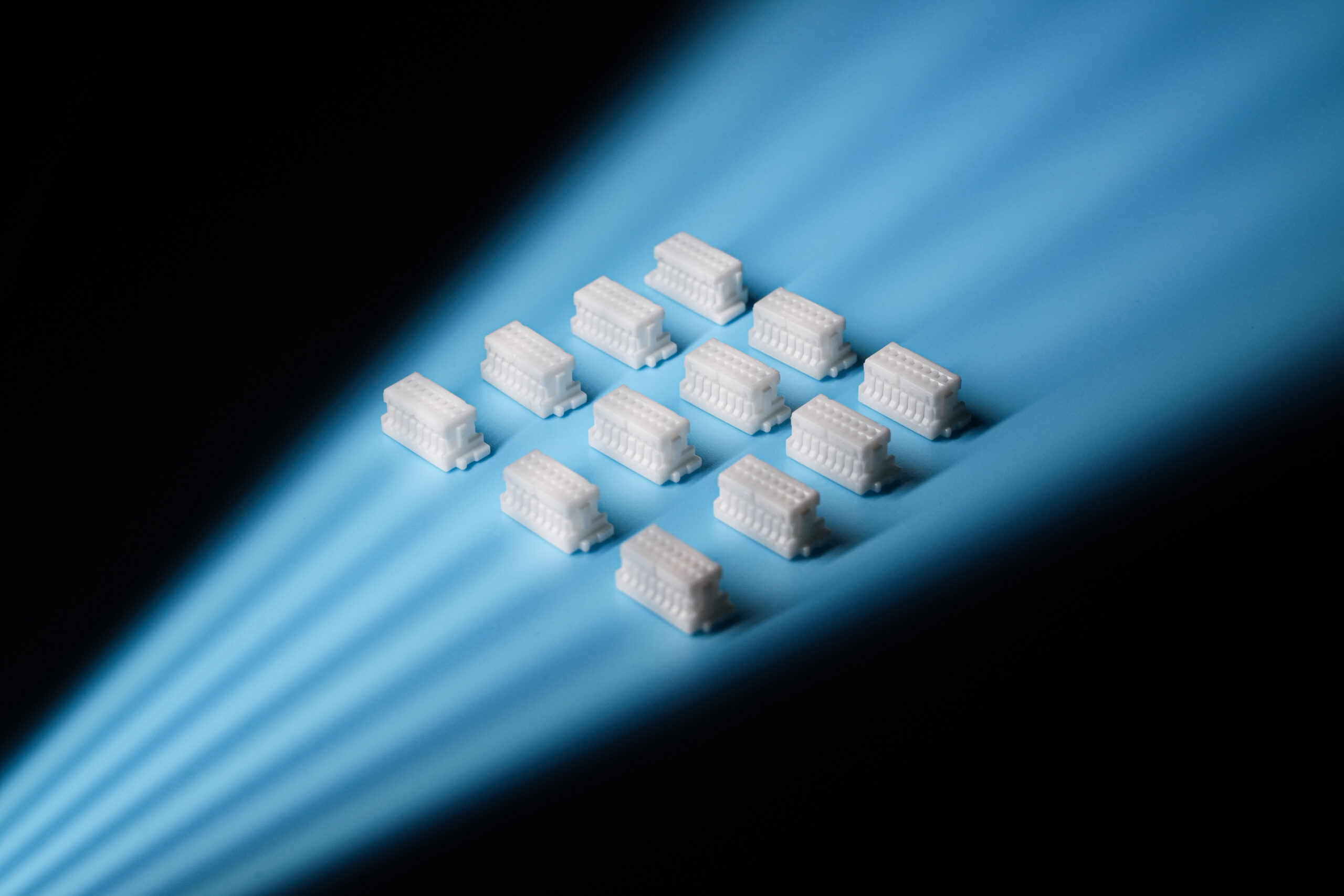

Absolutely. Leading Chinese manufacturers now produce components that are fully interchangeable with parts from top global brands. These parts not only meet but often exceed international automotive standards like IATF 16949, ensuring full compatibility and performance without any compromise on quality.

A Focus on Interchangeability and Performance

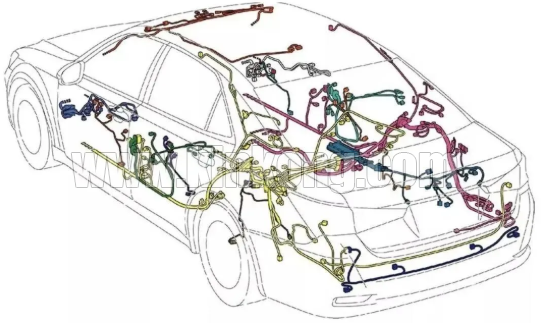

Let’s be direct. Your engineers need parts that are a 1-to-1 replacement for what they are using now. They need components that fit perfectly, perform reliably under stress, and don’t require any redesign of the harness. This is where we, as a manufacturer, have focused our efforts for over a decade. For example, our automotive connectors and terminals are designed to be direct equivalents to those from established brands. We use the same high-grade materials and follow the same rigorous testing protocols for vibration, temperature extremes, and chemical resistance.

Last year, a major Tier 1 supplier for a German car brand approached us. They were skeptical. They sent us a sample of a complex connector they were sourcing from a legacy European supplier. Their challenge was simple: “Match this, and prove it.” We delivered.

- Dimensional Accuracy: We used 3D scanning and precision molding to create a part with identical dimensions.

- Material Performance: We used the same grade of PBT plastic and phosphor bronze for the terminals.

- Validation Testing: Our in-house lab ran a full validation suite, sending them a report showing our part performed identically in every test.

They placed a trial order, and now we are one of their key suppliers. This isn’t a story about being cheaper; it’s a story about being an equal, more cost-effective partner.

How Does This Strategy Directly Impact Your Bottom Line?

Ultimately, every decision comes down to numbers. You need to present a clear case for cost savings and efficiency gains to your management. How does sourcing from China translate into real, measurable benefits for your company?

This strategy directly reduces your Bill of Materials (BOM) cost by leveraging China’s labor advantages and production scale. This leads to higher profit margins, a more competitive position when bidding for new projects, and a more resilient, simplified supply chain.

Breaking Down the Cost and Efficiency Gains

The financial benefits are clear and multi-faceted. First, there’s the direct cost saving on components. Because of lower labor costs and mature, high-volume production, a connector, terminal, or silicone seal from a top Chinese supplier can be significantly more affordable than its European or American equivalent, without sacrificing quality. This immediately lowers your BOM for every harness you produce.

Second, you gain efficiency. When you source multiple components—like connectors, terminals, and seals—from a single, reliable partner like Kinkong, you simplify your logistics. This means:

- Reduced Administrative Overhead: Fewer suppliers to manage, vet, and process invoices for.

- Streamlined Logistics: Consolidated shipments reduce freight costs and customs complexity.

- Improved Inventory Control: More reliable lead times from a concentrated supply base allow for leaner inventory management.

I remember helping Mike, the supply chain manager I mentioned earlier, run the numbers. By shifting just three key components for one of his major projects to us, he calculated a 15% reduction in the total cost for those parts. More importantly, he reduced his supplier count for that project by two, saving his team hours of work each week. That’s the real power of this strategy: it’s not just about cost, it’s about making your entire operation leaner and more robust.

Conclusion

To stay competitive, wiring harness makers must adapt. Shifting your component sourcing to China’s mature, high-quality, and cost-effective supply chain is the most practical and impactful strategy available today.